Fachpack 2025

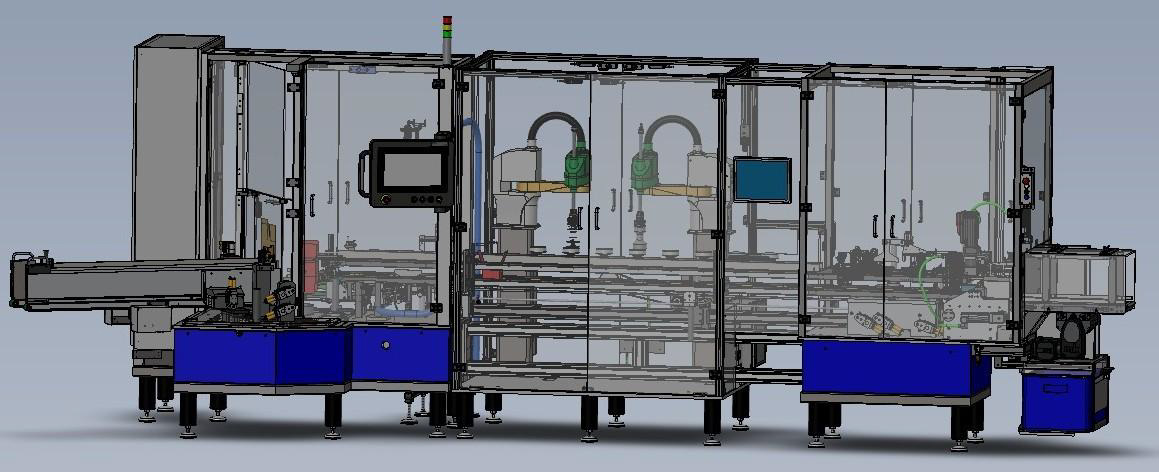

At Fachpack 2025 in Nuremberg this year, BRUNNER is presenting a fully automatic vertical cartoner, type VCL 180S, equipped with several additional functions.

These enable, for example, active folding box opening using counter-suction cups during the rotary folding box opening process. A total of nine electric actuators for almost all adjustment spindles also ensure reproducible format changes.

The machine on display is equipped with an automatic feeder system for cosmetic jars or bottles. Two Schneider Electric SCARA robots, type RS-P6 60 with a 300 mm Z-axis, are used for this purpose. Thanks to complete integration into the modern PacDrive 3 control system from Schneider Electric, the interface problems that are otherwise common when using robots with third-party control systems are eliminated.

Another special feature is jar recognition using a camera system from Keyence. This allows the often very high-quality jars to be completely inspected. They can be processed without touching each other, ensuring extremely gentle transport and ensuring safe feeding of even products that are not allowed to get backed-up on a conveyor, for example, due to their asymmetrical shape.

Depending on the folding box and product size, up to 80 folding boxes can be processed per minute. The cartoner is equipped for folding boxes with a tuck-in closure on both sides, as well as a combination of a glue closure on the bottom and a tuck-in closure on the top. At the cartoner's exit, the finished products can be transferred either upright or horizontally on the outfeed conveyor for further processing.

The system is operated using the optional 15" PC-based HMI from Schneider Electric.

Moving to a new location ...

Just in time for the 20th anniversary since the re-founding of Brunner Engineering GmbH & Co. KG, the new production building was inaugurated on October 22, 2021. During a barbecue event, the employees celebrated the opening in the assembly area of the hall until late at night, together with current owner, Ralf Mohr.

The basis for a modern and future-oriented production facility was created on the new property with approx. 4,600 m² at Schlosserstraße 11. The building has a floor space of 1,250 m² with 2 storeys of office area.

The issue of sustainability had a significant influence on the entire planning. The building was therefore constructed to KfW standard 55. An efficient air-to-water heat pump supplies the underfloor heating for the office area during the cold seasons. In summer, additional air-conditioning units create a pleasant working atmosphere.

In the production area, modern air-conditioning split units are used, which provide a pleasant working climate via textile hoses, both in winter and in summer.

A large-scale photovoltaic system with an output of over 99 kWP generates the necessary energy. Surplus electricity is fed into the electricity grid

The new build made it possible to meet the ever-increasing demands of the market, as the previous location had increasingly reached its limits over the past 5 years. The steady growth along with the constant advancement of technologies in the field of folding box packaging machines made an investment in the future inevitable. The new premises now offer sufficient space for the necessary spatial and personnel resources for the coming years.